Design ideas for low-voltage wiring harnesses in automobiles

Published Time:

2023-06-14

概要: For wire harness engineers, the development ability of wire harness cost reduction can directly reflect their business level. The reduction of wire harness cost can directly lead to the growth of company profits. Moreover, wire harness cost reduction often leads to wire harness weight reduction. Therefore, cost reduction design is an ability that can shape the core value of wire harness engineers themselves. This article provides ten ideas for wire harness cost reduction design.

Reasonable arrangement of electrical components

The wiring harness connects all electrical appliances in the vehicle, serving as a medium for energy transmission and signal interaction of electrical components. The layout of electrical components in the vehicle greatly affects the direction and layout of the wiring harness, and also affects the cost of the wiring harness. Therefore, during the virtual prototype stage of the entire vehicle, as a wiring harness engineer/system engineer, one should participate in determining the layout plan of the electrical components of the vehicle. For example:

1) The engine compartment fuse box should be on the same side as the cab fuse box, and the length of the power line between the engine compartment fuse box and the cab fuse box should be minimized as much as possible

2) The battery, DCDC/generator, and engine compartment fuse box should be located on the same side as much as possible and close to each other, which can greatly shorten the length of the power cord

Below are several examples of mass-produced vehicle models to illustrate how the placement of electrical components affects the cost of wiring harnesses.

Figure: Engine room layout diagram

Figure: Engine room layout diagram

Figure: Engine room layout diagram

Figure: Engine room layout diagram

From the picture, we can see that the batteries and fuseboxes of the Golf, Magotan, GS8, and Jeep cars are located on the same side of the engine compartment and near the firewall. This can greatly shorten the length of the power cord, which is beneficial for controlling the cost of the wiring harness.

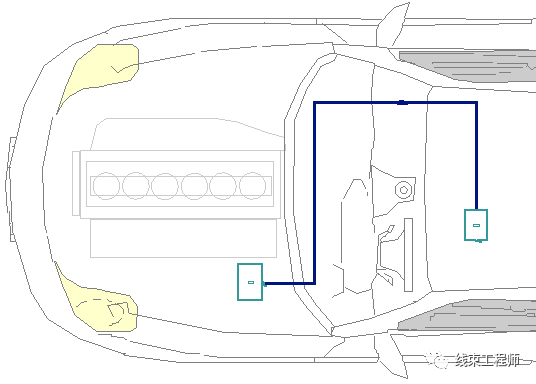

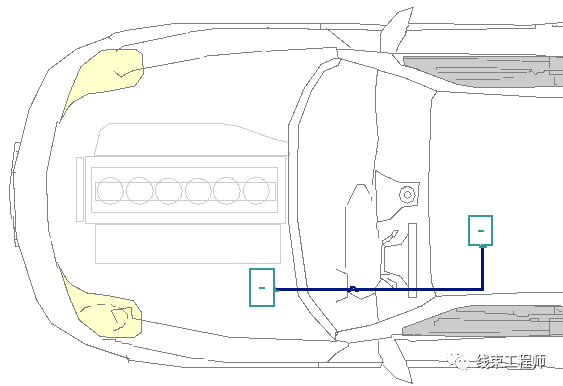

2、 Optimization of wiring harness circuit layout path

Loop path optimization refers to minimizing the path of the circuit during the design process. While shortening the length of the wire, it can reduce voltage drop, which is beneficial from the perspectives of cost, lightweight, and design reliability. For example:

Figure: Trend before circuit optimization

Figure: Trend after circuit optimization

From the above figure, we can see that after optimizing the circuit path in the wiring harness, a very long line length can be shortened.

3、 Reasonable wiring harness fixation and wrapping protection design

Effectively avoiding some over design can help reduce the cost of wiring harnesses. In general, common over design is used for fixing wire harnesses, and wire harness wrapping design is particularly common, such as:

1) When fixing the wiring harness, for indoor floor wiring harnesses, a distance of about 300 between two ties is fixed using ties. If a fixed point is set at an interval of 150, there will be design waste for the wiring harness design, which not only increases the cost of the wiring harness product but also increases the labor time for final assembly. These can be completely avoided.

2) We can use flower wrap to wrap the indoor floor wiring harness. If designed to be fully wrapped, it increases the cost of the wiring harness and also leads to the wiring harness being too rigid, which is not conducive to wiring harness assembly.

3) For the use of corrugated pipes, some cover the entire cabin wiring harness with heat-resistant corrugated pipes, and even some indoor wiring harnesses.

Figure: Binding Scheme for BMW 3 Series Floor Harness (Flower Wrapping)

Figure: Volkswagen Golf's floor harness binding scheme (flower wrapping)

4、 From the perspective of principle design

Most of the time, when we design wiring harness cost reduction, we will think about optimizing the principles, such as considering the following aspects:

1) Optimization of fuse location, capacity, merging and sharing of fuses

2) Optimize the wire diameter and wire type based on the capacity of the fuse

3) Is it grounded nearby and is the grounding distribution reasonable, such as adding a new grounding point for the ceiling harness

4) Optimization of riveting point positions for circuit wires, etc

Regarding principle design optimization, it is necessary to consider it from the beginning of the design process. In addition, during the prototype production process, relevant experiments need to be supplemented for design verification and optimization, forming a closed-loop design. We cannot just stay at the theoretical level. On the one hand, it is because the theoretical parameters provided by the prototype are not completely consistent with the actual parameters, and there may even be significant discrepancies. We cannot control this and need to verify it; On the other hand, existing selection theories are not yet fully universal, and most of them are also summaries of experience.

5、 Integration and networking of module functions

The integration referred to here refers to integrating the functions of modules, making multiple modules into one large module, which can reduce the dependence of each module on hard wire circuits. For wiring harnesses, many wires can be omitted, which can reduce the cost of wiring harnesses and reduce the weight of the entire vehicle.

Networking can also greatly reduce the use of wires, such as the CAN bus, Lin bus, etc. We boldly predict that the integration of modules and regionalization of networks will be the direction of future automotive development. Perhaps in the future, there will be as few wiring harnesses in cars as there are in current computer cases.

6、 Reasonably divide the wiring harness configuration

To meet the needs of different consumers, many companies may come up with many models and configurations for the same car, even in the range of 20 to 30 models. Our marketing department believes that simply adding or reducing the functional configuration of the entire vehicle is a matter of whether or not to install the components. However, for the wiring harness, any change in functional configuration, from the perspective of the entire vehicle principle, will bring about wiring differences in the wiring harness (except for software configuration items).

If we were to differentiate the wiring harnesses for each configuration model at this time, it would inevitably increase the number of wiring harness drawings. This can result in the following consequences (including but not limited to):

1) There are a wide variety of wire harnesses, and both automobile OEMs and wire harness suppliers have increased management costs and warehousing costs.

2) Added a significant amount of workload to generating logistics

3) Adding a lot of uncertainty to the assembly of the entire vehicle, making it easy to install incorrectly

4) Increased cost of design changes and product optimization

Based on this, we can start from the perspective of functional configuration, coordinate management, and merge the relevant configuration drawing numbers. Even in the development stage, we can try to achieve that all sample vehicles use the same configuration of wiring harnesses. After development and verification, we can differentiate the wiring harness configuration functions. At the same time, combined with product sales, we can optimize the wiring harness configuration of popular models in a targeted manner in the later stage, further reducing wiring harness costs.

7、 Platformized selection of wire harness components

What is the platform based selection design of wiring harnesses? The so-called platformization refers to

Platformized selection has two advantages: firstly, it can ensure the reliability of the design, as there are already mass-produced models in use; One reason is that the price of platformized parts is better because many car models use the same component, and as the usage increases, lower prices can be obtained.

The platform based design of wiring harnesses means that we need to achieve

1) The platform based selection of buckles and ties should avoid new development parts. Even if new parts are needed, suppliers should choose products with high volume, and other main engine manufacturers should produce parts for vehicle models.

2) Platformized selection of binding materials such as tape and corrugated pipes

3) Platformized Selection of Rubber Parts

4) Platform based selection of wire diameter and wire color

5) Platformization of terminals and connectors, platformization of inline components, and platformization of device side connectors

Regarding the platformization of connectors mentioned above, for wire harness groups, most of the time, we can only control the wiring harness connectors, and the plug-in connection of components is very controlled by ourselves, after all, the wiring harness is a matching component. Therefore, the platformization of connectors needs to be promoted from the electrical department level, even at the hospital level. The platform based selection of wiring harness design is a top-down process.

8、 Localization selection of wire harness components

The localization of components is actually coordinated with the aforementioned "platform based selection". Localized selection is not only beneficial for cost, but also for shortening the supply cycle.

In the process of wire harness development, due to the particularity of the wire harness, during the prototype production process, unlike other parts, the wire harness can be delayed or even repaired, and is always required to arrive in advance. Therefore, selecting many inlet sub components has a significant impact on delivery time and also affects development costs, increasing development risks such as having to accept replacement parts.

9、 Optimization design of wire harness products

In the development process of wire harness products, the optimization design of layout should not only be in the data stage, but also run through every process of wire harness design and development.

In the prototype trial production stage, the wiring harness products have already been materialized. For the first prototype trial production, there will inevitably be various problems such as the wiring harness size being too long/too short, and the branch point position being unreasonable. As a wiring harness engineer, we should make full use of the resources from each prototype trial production, optimize product design, optimize the position and length of wiring harness branch points, and keep records and verify each design change. After repeating for 3 rounds, the optimization design of wire harness size and materials will also bring considerable benefits in reducing cost and weight of the wire harness.

10、 Cost reduction for raw material procurement, production, manufacturing, and transportation by suppliers

The first nine articles all discuss the cost reduction design of wiring harnesses from the perspective of design and development. Although the price of the product is determined by design, this does not mean that there is no other way to reduce the cost of wiring harnesses except for design optimization. In fact, there are still many opportunities for wire harness cost reduction, including the procurement channels of raw materials, optimization of manufacturing processes, control of defect rates, transportation routes, product packaging design, and so on.

This article elaborates on the idea of wire harness cost reduction from 10 perspectives. It should also be noted that the prerequisite for cost reduction of wiring harnesses should be based on product performance, and closed-loop design must be achieved to ensure the reliability of the optimized design after cost reduction. In addition, cost reduction of wiring harnesses is a systematic task that cannot be completed solely by a single wiring harness engineer in this project. It should be a special topic or a separate project that fully leverages the initiative of various groups such as design, procurement, marketing, and manufacturing, all of which cannot be separated from the attention of the company's high-level resources.

Hot News

Research on Reliability of Wire Harness Design

At present, modern science and technology have been effectively improved, and the automotive industry has also developed rapidly, becoming an indispensable part of people's lives. At the same time, the electrical equipment inside the car can connect each electronic component. Wire harness design plays an important role in automotive circuits, otherwise the functional requirements of the car cannot be met, as the improvement of car performance and the continuous application of new functions can meet the different needs of the car. Due to the increasingly complex internal structure of automobiles, the difficulty of installation, maintenance, and wiring of electrical appliances also increases. The weight required for the crossbeam will also increase with the increase of components, thereby reducing the reliability of the vehicle. This article analyzes the system design of automotive wiring harnesses and the selection of relevant raw materials, in order to provide reference for the reliability of automotive wiring harness design.

2023-06-14

Design ideas for low-voltage wiring harnesses in automobiles

For wire harness engineers, the development ability of wire harness cost reduction can directly reflect their business level. The reduction of wire harness cost can directly lead to the growth of company profits. Moreover, wire harness cost reduction often leads to wire harness weight reduction. Therefore, cost reduction design is an ability that can shape the core value of wire harness engineers themselves. This article provides ten ideas for wire harness cost reduction design.

2023-06-14

Why is the terminal resistance of the CAN bus 120 Ω

The terminal resistance of the CAN bus is generally 120 ohms. In fact, when designing, two 60 ohm resistors are connected in series, and there are usually two 120 ohm nodes on the bus. Most people who know a little about the CAN bus know this truth.

2023-06-14