Research on Reliability of Wire Harness Design

Published Time:

2023-06-14

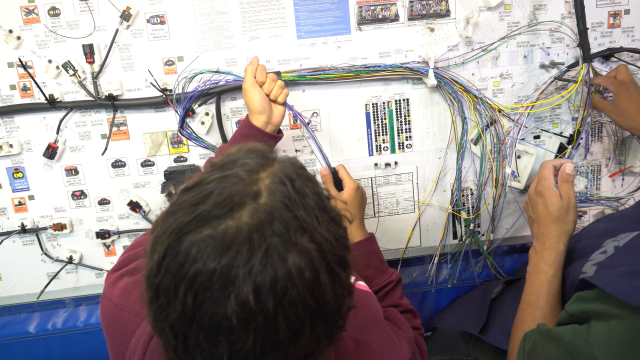

概要: At present, modern science and technology have been effectively improved, and the automotive industry has also developed rapidly, becoming an indispensable part of people's lives. At the same time, the electrical equipment inside the car can connect each electronic component. Wire harness design plays an important role in automotive circuits, otherwise the functional requirements of the car cannot be met, as the improvement of car performance and the continuous application of new functions can meet the different needs of the car. Due to the increasingly complex internal structure of automobiles, the difficulty of installation, maintenance, and wiring of electrical appliances also increases. The weight required for the crossbeam will also increase with the increase of components, thereby reducing the reliability of the vehicle. This article analyzes the system design of automotive wiring harnesses and the selection of relevant raw materials, in order to provide reference for the reliability of automotive wiring harness design.

Design and principles of automobile wiring harness layout

When designing the wiring harness layout, designers should fully consider the distribution and attribute characteristics of the entire vehicle's electronic equipment. The wiring harness can be roughly summarized into: front compartment wiring harness assembly, engine wiring harness assembly, instrument wiring harness assembly, floor wiring harness assembly, door wiring harness assembly, ceiling wiring harness assembly, battery wiring harness assembly, etc.

(1) Convenient installation of wiring harness assembly

When designing the configuration of automotive wiring harnesses, different design forms should be adopted for the wiring harness design based on different regions, usually using "H" and "E" layouts. The diameter of the metal port must be greater than the maximum external component diameter that passes through the port. If it cannot be reached, the wiring harness cannot pass through. The configuration of car wiring harnesses should minimize the addition of too many steps in the assembly of a full person vehicle, as their planned positions are different, resulting in different structures required. In order to facilitate installation, designers need to prepare at least two or more solutions when formulating the plan, and study the actual possibilities and advantages and disadvantages of each solution to determine whether the structure can meet the requirements of automotive circuits.

(2) The fixed structure of the wiring harness is easy to assemble

When designing the wiring harness fixing mode and structure, it is necessary to fully consider the assembly program of the components. In situations where there is not much increase, the reliability of the components should be sought. Simple, especially in narrow spaces such as side lines inside doors, body and interior decoration lines, and due to limited space, plastic clips or adhesive tapes must be fully installed in the metal plate holes when designing the fixing wiring harness structure and related functions Install perforated rubber clips with an installation force not exceeding 100N. In this case, normal standard components should be designed to use the type of standard components as much as possible, and the use of special tools for assembly and maintenance should be minimized through early design.

(3) Good maintainability

When a fault occurs in the power system, eliminate the fault in the shortest possible time and prevent damage to other components caused by the fault. For the convenience of maintenance in the later stage, when there are many plug-in components in the car, the fixed position of the circuit should be carefully considered. If necessary, wire harness slots or wire harness brackets can be added, and the exposed parts can be protected with corrugated pipes, so as to leave gaps between each area and avoid unnecessary interference from the parts. At the same time, the wiring harness layout needs to avoid high-temperature areas, with a gap distance of at least 160 millimeters left before. If high-temperature components cannot be avoided, insulation covers need to be added to protect the wiring harness from additional conflicts with the system, ensuring the convenience of wiring harness maintenance.

Selection and Aesthetic Design of Raw Materials for Automotive Wire Harnesses

(1) Selection of raw materials for automotive wiring harnesses

Designers in automotive circuit design must fully understand and respect the principles of the circuit, such as whether to select wires that match the color during the selection guidance process, as selecting the correct color of wires can minimize the occurrence of errors. At the same time, an appropriate cross-sectional area should also be selected, and the shortest spacing must be selected for wire connection. The ultimate goal is to correctly install wires on both sides of the connector, which can better analyze and study the overall wiring harness design of the car.

The most important link in the design is the selection of fuse and harness. We know that it is crucial to correctly select raw materials in Automotive design. Fuses belong to the protective components of automobiles, and their operating principle is to protect electronic devices during use. If the fuse selection is not reasonable, it will not be able to immediately fuse at the predetermined current value, and it will not serve the purpose of protecting electrical appliances. At present, most cars are composed of low-voltage wires with vinyl resin insulation, or thin-walled low-voltage wires for cars, which can be easily assembled by operators, and later maintenance and replacement will be simple and easy.

(2) Aesthetic Design of Automotive Wiring Harnesses

Regardless of the principles to be followed or the selection of materials for making automotive wiring harnesses, the most important thing is to let nature take its course, not to overly stretch the wiring, and to add aesthetic design on this basis. The wiring harness should be oriented in the same direction as the area where the electronic device is located, and it is recommended to adopt a horizontal and vertical straight design as much as possible to avoid using oblique direction design to save materials. If the wiring harness is found to be too messy during layout, it is recommended to use the wiring harness protective plate reasonably in this part. In the design plan, it is necessary to comprehensively consider the overall components of the car, and combine the wiring harness layout to avoid potential risks as much as possible before starting, providing greater space for later manufacturing and assembly. Firstly, the designers should arrange the wiring harness direction reasonably to choose the optimal method to ensure the operational performance of the electrical appliances.

Reliability Analysis of Automotive Wiring Harness System

China has always supported the promotion of reliability implementation, and has invested a lot of effort in research to better improve reliability. The improvement of automotive wiring harness reliability is mainly carried out from the following aspects:

(1) Reliability analysis of terminals and connectors

One of the main contents of the reliability of wiring harness systems is terminals and connectors, which are key components of automotive wiring harness systems and have very important significance in wiring harness systems. The damage to the wiring harness system is mostly caused by problems with the terminals and connectors, such as terminal aging, and other issues such as looseness and damage in the middle of the connectors that have occurred for too long. This issue is a very small detail in daily life, but it directly affects the reliability of the wiring harness system. So in wiring harness design, it is necessary to take a series of measures to effectively improve the reliability of segments. It is worth noting that selecting appropriate connectors and plugins is very important, and attention should be paid to the temperature of the connector, as well as the maximum allowable current, especially the working environment and temperature. The most important thing is to effectively prevent damage to the terminals and connectors caused by corrosive gases and liquids.

(2) Wiring harness protection reliability

Designers need to analyze the reliability of wiring harness protection from the perspective of integrity, so it is necessary to develop a series of reliability measurements. In the selection process, packaging materials must undergo detailed and integrated testing, and then select the materials with the highest integration performance, sample and inspect the specific content of each step, and remove non-conforming products. The fixing design of wire harnesses generally uses ties, clamps, and bracket guards, etc. Their main function is to fix the direction of the wire harness, reduce friction, and avoid safety hazards.

Ties are the most commonly used materials in fixed orientations, and most of the fixation is done using them. We often use Japanese style straps, such as P66 materials such as long punch universal lifting type, T-shaped, plug connectors, pipe clamps, etc. Generally used in areas with limited space and inability to drill holes, the bracket guard has poorer usability compared to the two above, and generally has higher manufacturing costs. The structural shape of each car is different, so the design of the bracket guard will also be different. In order to better enhance the reliability of wire harness protection, there is optimization space for each type of material used for wire harness fixation. While improving the wire harness scheme, designers can further study the quality of fixed wire harnesses, reduce costs, and improve economic benefits.

(3) Reasonable layout reliability

Reasonable configuration and distribution can improve the structure and reliability of wiring harnesses. Reasonable configuration can effectively optimize the complexity of wiring harness design and avoid many risks in wiring harness manufacturing and installation. During the installation and testing process, optimizing the size and diameter of the wiring harness through reasonable configuration and improving human friendliness affects the reliability of the entire vehicle system.

However, before layout, the length of the wiring harness is determined based on the actual configuration of the electrical appliances on the vehicle. In design, if the length of the wiring harness is too long, it will waste space and materials to make the wiring harness vertical, causing the vehicle to collide with the metal plate and generate sound due to friction during movement. Due to the above reasons, the actual fixing strength of the wiring harness should be increased, which helps to improve the reliability of the wiring harness and provides a good foundation for the actual assembly process in the later stage.

conclusion

Automotive wiring harnesses are ubiquitous in the organization structure, known as the "nerve" of automobiles, which has a direct impact on the safety and comfort of automotive use. Therefore, automotive wiring harnesses have very high requirements for design and the selection of their raw materials. In the process of wiring harness design, targeted design should be carried out based on the working conditions, functionality, etc. of the wiring harness to improve the feasibility of the design, ensure the maximum adaptation of the wiring harness raw materials to the working environment, and ensure the stability and reliability of the overall performance of the vehicle after it is put into use.

Hot News

Research on Reliability of Wire Harness Design

At present, modern science and technology have been effectively improved, and the automotive industry has also developed rapidly, becoming an indispensable part of people's lives. At the same time, the electrical equipment inside the car can connect each electronic component. Wire harness design plays an important role in automotive circuits, otherwise the functional requirements of the car cannot be met, as the improvement of car performance and the continuous application of new functions can meet the different needs of the car. Due to the increasingly complex internal structure of automobiles, the difficulty of installation, maintenance, and wiring of electrical appliances also increases. The weight required for the crossbeam will also increase with the increase of components, thereby reducing the reliability of the vehicle. This article analyzes the system design of automotive wiring harnesses and the selection of relevant raw materials, in order to provide reference for the reliability of automotive wiring harness design.

2023-06-14

Design ideas for low-voltage wiring harnesses in automobiles

For wire harness engineers, the development ability of wire harness cost reduction can directly reflect their business level. The reduction of wire harness cost can directly lead to the growth of company profits. Moreover, wire harness cost reduction often leads to wire harness weight reduction. Therefore, cost reduction design is an ability that can shape the core value of wire harness engineers themselves. This article provides ten ideas for wire harness cost reduction design.

2023-06-14

Why is the terminal resistance of the CAN bus 120 Ω

The terminal resistance of the CAN bus is generally 120 ohms. In fact, when designing, two 60 ohm resistors are connected in series, and there are usually two 120 ohm nodes on the bus. Most people who know a little about the CAN bus know this truth.

2023-06-14